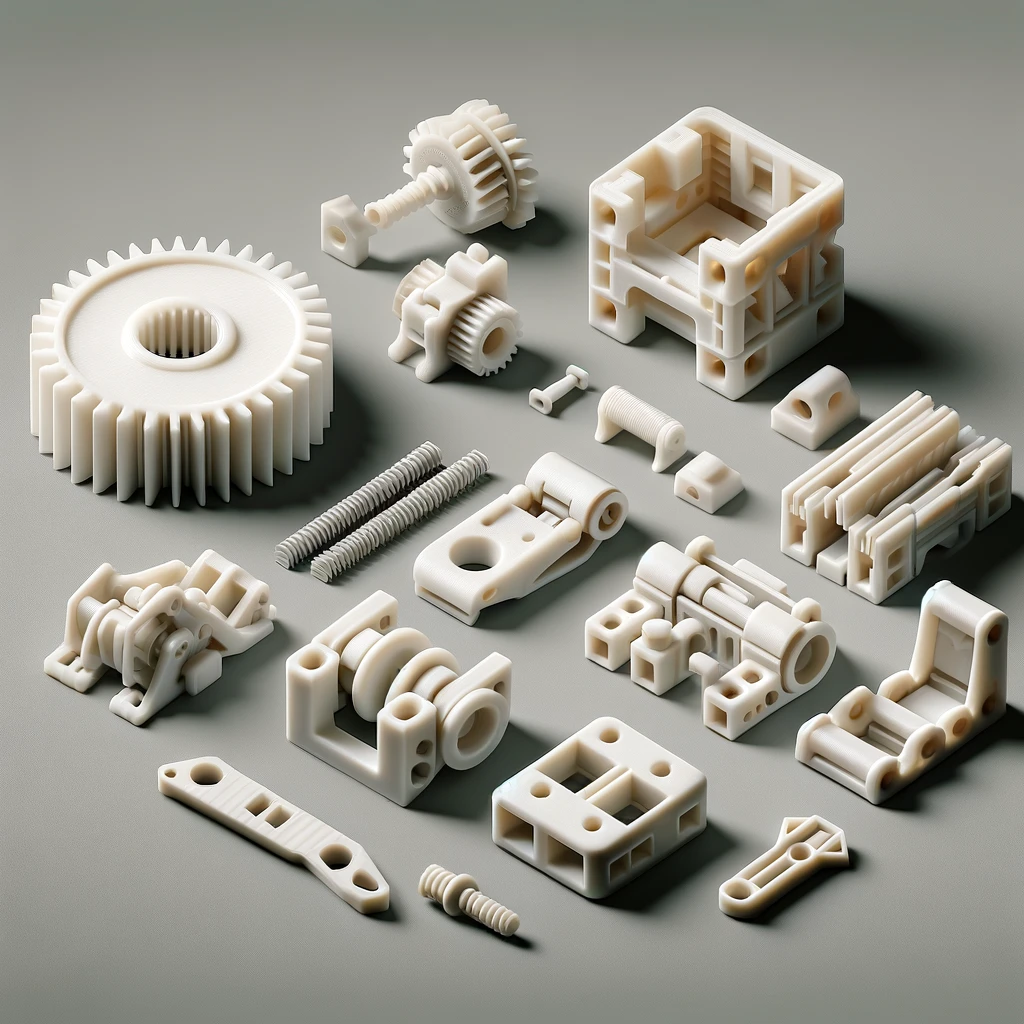

The landscape of industrial manufacturing is witnessing a significant shift with the integration of 3D printing technologies. These advancements are not just enhancing the capabilities of industries but are also providing a stark contrast to traditional manufacturing methods. In this blog, we explore various 3D printing technologies and their comparative advantages for industrial applications.

3D printing, or additive manufacturing, offers a range of technologies, each suited to different industrial needs. The most prominent among these are Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS).

FDM

FDM is widely used for its cost-efficiency and strong, durable materials, making it ideal for creating functional parts and prototypes that need to withstand operational stresses. It’s particularly popular in automotive and aerospace sectors for producing complex, low-volume components quickly.

SLA

SLA technology stands out for its exceptional detail and surface finish. Industries that require highly detailed prototypes, like dental, medical, and jewelry manufacturing, find SLA indispensable. Its ability to produce watertight parts makes it perfect for creating precise molds and consumer-ready products.

SLS

SLS, on the other hand, excels in creating parts that are robust and can withstand functional testing. It’s favored in the production of high-performance, durable parts for aerospace and automotive applications. Unlike FDM and SLA, SLS doesn’t require support structures, allowing for more complex geometries with less waste.

The choice of technology often depends on the specific requirements of the production, including material properties, mechanical strength, detail resolution, and cost-effectiveness. With 3D printing becoming more accessible, industries are able to leverage these technologies to achieve high efficiency, reduce waste, and shorten product development cycles.

3D printing technologies are reshaping the manufacturing landscape by providing diverse solutions that cater to the varied needs of modern industries. By understanding the specific capabilities and advantages of each 3D printing technology, businesses can make informed decisions to optimize their manufacturing processes, enhance product quality, and drive innovation.

#KM3D #3DPrintingTech #IndustrialManufacturing #AdditiveManufacturing #FDM #SLA #SLS #ManufacturingInnovation #TechComparison #3DPrintingSolutions #RapidPrototyping #Automotive3DPrinting #Aerospace3DPrinting #Medical3DPrinting #Jewelry3DPrinting #EfficientManufacturing #ProductDevelopment #InnovativeManufacturing #TechnologyInIndustry #IndustrialRevolution