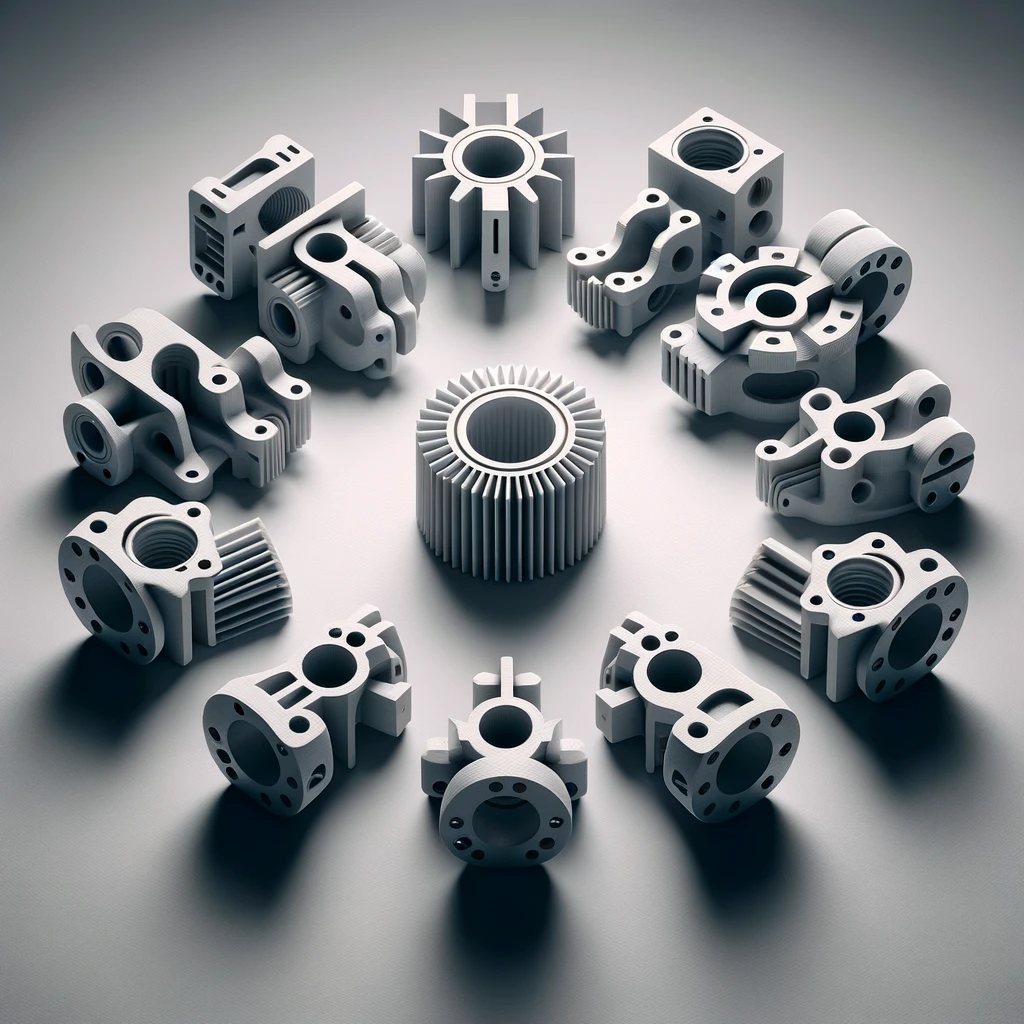

Metal 3D printing, a type of additive manufacturing, is revolutionizing how we create components across industries. By building parts layer by layer, it offers the ability to produce complex geometries that are challenging or impossible to achieve with traditional manufacturing methods.

The process starts with a digital design, which is then brought to life using techniques like Direct Metal Laser Sintering (DMLS) or Selective Laser Melting (SLM). These methods use high-powered lasers to melt and fuse fine metal powders layer by layer. The result is a metal part with excellent mechanical properties, ideal for both prototyping and production.

Materials in metal 3D printing vary from common metals like stainless steel and aluminum to exotic alloys like titanium and Inconel. Each material is chosen based on the specific needs of the part, such as durability, flexibility, or thermal resistance.

One of the biggest advantages of metal 3D printing is its speed. Prototypes can be produced much faster than with conventional methods, allowing for rapid testing and development cycles. This accelerates innovation by enabling engineers to refine designs quickly based on real-world testing.

Another benefit is waste reduction. Traditional subtractive manufacturing often starts with a solid block of material and removes parts of it, which can lead to significant material waste. Metal 3D printing only uses material where it's needed, which is more sustainable and cost-effective.

For industries like aerospace, automotive, and healthcare, metal 3D printing is not just a tool for creating prototypes but is increasingly being used for end-use parts. The ability to customize each part without the need for new tooling or molds opens up new possibilities for personalized products and complex, lightweight designs.

KM3D.ca is dedicated to leveraging this technology to help innovators and businesses bring their visions to life. Whether it's a single prototype or a small batch of specialized components, we offer the expertise and technology to make it happen.

#Metal3DPrinting #AdditiveManufacturing #Prototyping #DMLS #SLM #Engineering #Innovation #KM3D